Optimal Pelletizing Performansı için Pellet Mill Die Nasıl Seçilir

2025-12-29

.gtr-pellet-dies-comp-9876 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

color: #0056b3;

text-align: left;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

font-weight: bold;

margin-top: 30px;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

border-bottom: 1px solid #eee;

padding-bottom: 5px;

}

.gtr-pellet-dies-comp-9876 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-pellet-dies-comp-9876 p strong {

color: #0056b3;

}

.gtr-pellet-dies-comp-9876 ul {

list-style: none !important;

padding-left: 20px !important;

margin-bottom: 15px;

}

.gtr-pellet-dies-comp-9876 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 18px;

line-height: 1;

top: 0;

}

.gtr-pellet-dies-comp-9876 ul li strong {

color: #0056b3;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info {

font-size: 14px;

margin-top: 20px;

text-align: left !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a {

color: #0056b3;

text-decoration: none;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a:hover {

text-decoration: underline;

}

@media (min-width: 768px) {

.gtr-pellet-dies-comp-9876 {

padding: 30px 40px;

max-width: 900px;

margin: 0 auto;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

margin-bottom: 25px;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

margin-top: 40px;

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 p {

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 ul {

padding-left: 25px !important;

}

.gtr-pellet-dies-comp-9876 ul li {

padding-left: 25px;

margin-bottom: 10px;

}

.gtr-pellet-dies-comp-9876 ul li::before {

font-size: 20px;

}

}

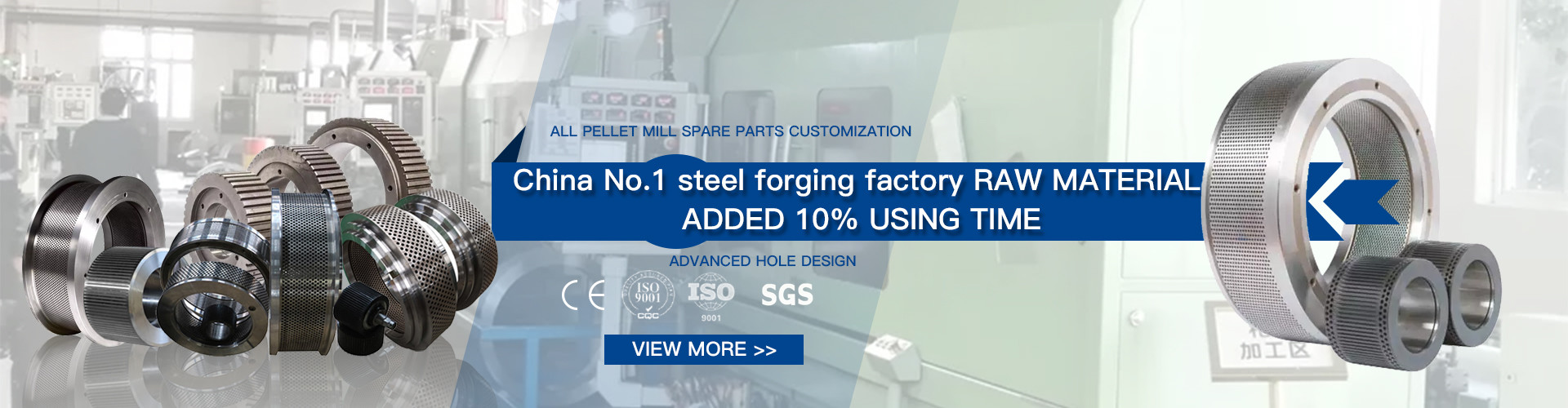

Yüksek Kaliteli Pellet Mühendisi En Optimal Pelletizing Performansı İçin Ölçüyor

Yüksek performanslı pelet değirmenleri üreten önde gelen bir üretici olarak, CPM, SZLH, PTN, Bühler,ve daha fazlasıİster hayvan yemi, ister biyokütle, ister organik gübre üretimi ile ilgileniyorsunuzdur, pellet matörlerimiz maksimum verimlilik, dayanıklılık ve tutarlılık sağlamak için tasarlanmıştır.

Pellet Mill Die nedir?

Pellet değirmeninin ölçeği, pelletleme işleminde kritik bir bileşendir.toz olarak kullanılan malzemenin sıkıştırılması ve tek tip pellets haline getirilmesi içinMatre, basınç ve ısı uygulayarak, nakliye, depolama ve besleme için ideal olan kompakt, yoğun peletler oluşturmak için rulolarla birlikte çalışır.

Pellet Die Yeteneklerimiz

En uygun uyumluluğu ve performansı sağlamak için tam spesifikasyonlara göre döşeme üretmek için donatılmış bulunuyoruz.

Özel üretim (resim veya numune bazlı)

Büyük pelet fabrikası modelleri için standart ölçekler

Malzeme seçimi (örneğin paslanmaz çelik, alaşımlı çelik)

Çukur Boyutları 1.0 mm'den 12.0 mm'ye kadar

Çiğ maddenin ve uygulamanıza uygun sıkıştırma oranları

Uyumlu Pellet Mill Markaları

Çeşitli pellet fabrikası modelleri için yedek ve özel ölçekler üretiyoruz, bunlardan bazıları:

CPM

SZLH

PTN

Bühler

Ve diğer popüler uluslararası markalar

Tüm kalıplar boyut doğruluğu, sertlik ve yüzey finişi için tam olarak test edilir ve denetlenir.

Neden Bizim Pellet Matları'nı Seçin?

Hassas Mühendislik: CNC işlenmiş ölçekler yüksek çıkış ve tutarlı pelet kalitesini sağlar.

Özel Çözümler: Farklı hammaddeler (mısır, zencefilli, buğday kanatları vb.) için özel sıkıştırma oranları ve malzemeler.

Uzun kullanım süresi: Kullanıma dayanıklı malzemelerden yapılmış ve dayanıklılık için ısı ile tedavi edilmiştir.

Hızlı Teslimat: Dünya çapında zamanında teslimat için verimli üretim ve lojistik.

Teknik Destek: Ölçü seçimi ve pelet fabrikası optimizasyonu için uzman danışmanlığı.

Başvurular

Pellet matörlerimiz geniş çapta kullanılıyor:

Hayvan Besinleri Üretimi (kuş, sığır, koyun, balık)

Biyokütle Pelletizing (ahşap, saman, pirinç kabuğu, vb.)

Organik gübre kabuğu

Endüstriyel ve Tarımsal Atıkların Pelletizasyonu

Bugün Bizimle İletişim Kurun

Güvenilir, yüksek performanslı pellet değirmenleri arıyorsunuz? Özel çözümler ve rakipsiz kalite için bizimle işbirliği yapın. Bize numunenizi, çiziminizi veya özelliklerinizi gönderin,Ve ihtiyaçlarınıza mükemmel bir şekilde uyan bir mat üreteceğiz..

E-posta adresi:apexbiomass0909@gmail.comTelefon: [wa/line: +86- 18562307530]

Daha fazla göster

Biyokütle Pellet Mill Makine Endüstrisi için Küresel Pazar Görünümü

2025-12-24

.gtr-container-x7y2z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

box-sizing: border-box;

width: 100%;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-x7y2z9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

text-align: left;

color: #0056b3;

}

.gtr-container-x7y2z9 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

line-height: 1.6;

color: #444;

}

.gtr-container-x7y2z9 p:last-child {

margin-bottom: 0;

}

.gtr-container-x7y2z9 strong {

font-weight: bold;

color: #000;

}

@media (min-width: 768px) {

.gtr-container-x7y2z9 {

padding: 30px;

}

.gtr-container-x7y2z9-title {

margin-bottom: 25px;

}

.gtr-container-x7y2z9 p {

margin-bottom: 20px;

}

}

Biyokütle Pelet Değirmeni Makine Sektörü için Küresel Pazar Görünümü

Küresel pazarı Biyokütle Pelet Değirmeni Makineleri yenilenebilir enerji politikaları ve artan enerji maliyetleri tarafından yönlendirilen istikrarlı bir büyüme yaşıyor. Avrupa, en büyük pelet tüketen bölge olmaya devam ederken, Kuzey Amerika ve Asya-Pasifik pazarları hızla genişliyor.

İhracata yönelik pelet fabrikaları, uluslararası kalite standartlarını karşılamak için yüksek kapasiteli Biyokütle Pelet Değirmeni Makinelerine güvenmektedir. Pelet dayanıklılığı, nem içeriği ve boyut tutarlılığı, küresel ticaret için kritik faktörlerdir.

Üreticiler, hammadde türüne, üretim kapasitesine ve yerel enerji düzenlemelerine göre giderek daha fazla özelleştirilmiş çözümler sunmaktadır. Bu esneklik, biyokütle pelet ekipmanlarını çeşitli pazar ihtiyaçlarına uyarlanabilir hale getirir.

Dünya çapında yenilenebilir enerji yatırımları arttıkça, Biyokütle Pelet Değirmeni Makinesinin sürdürülebilir enerji üretimi ve çevre korumayı destekleyen önemli bir teknoloji olmaya devam etmesi bekleniyor.

Daha fazla göster

Biyokütle Pelet Değirmeni Makineleri, Temiz Isıtma Yakıtına Yönelik Artan Talebi Destekliyor

2025-12-24

Biyomassa Pellet Mill Makineleri, Temiz Isıtma Yakıtına Artan Talebi Destekliyor

Temiz ısıtıcı yakıt talebi özellikle Avrupa ve Kuzey Amerika'da artmaya devam ediyor.Biyokütle Pellet Mill Makinesibüyük ölçekli pelet üretimini mümkün kılarak bu talebi karşılamada merkezi bir rol oynar.

Biyomassa peletleri, konut pelet sobalarında, şehir ısıtma sistemlerinde ve endüstriyel kazanlarda yaygın olarak kullanılır.Uyumlu boyutları ve yüksek yoğunlukları otomatik besleme ve verimli yanma sağlar.

Endüstriyel kullanım için tasarlanmış pelet fabrikası, 24 saat, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 7 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 8 gün, 9 gün, 8 gün, 8 gün, 9 gün, 9 gün, 9 gün, 9 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 gün, 10 günve pelet tarama ekipmanları genellikle tam üretim hatlarına entegre edilir..

Kömür ve fosil yakıt kullanımındaki artan kısıtlamalarla birlikte, biyomassa peletleri tercih edilen bir alternatif haline geliyor.Biyokütle Pellet Mill Makinelerine yapılan yatırımlar küresel pazarlarda büyümeye devam ediyor.

Daha fazla göster

Teknolojik Gelişmeler Biyogaz Pellet Fırın Makinelerinin Verimliliğini Artırıyor

2025-12-24

Teknolojik Gelişmeler Biyokütle Pelet Değirmeni Makinelerinin Verimliliğini Artırıyor

Sürekli inovasyon, son yıllarda Biyokütle Pelet Değirmeni Makinesi performansını önemli ölçüde iyileştirdi. Üreticiler artık çıktıyı artırmaya, enerji tüketimini azaltmaya ve ekipman ömrünü uzatmaya odaklanıyor.

Önemli bir gelişme, kalıplar ve silindirler için yüksek mukavemetli alaşımlı çelik kullanımıdır. Bu, aşınma direncini artırır ve makinelerin uzun süre ağır yükler altında çalışmasını sağlar. Otomatik yağlama sistemleri ayrıca bakım gereksinimlerini azaltır.

Akıllı kontrol sistemleri de standart hale geldi. Operatörler sıcaklığı, basıncı ve motor yükünü gerçek zamanlı olarak izleyebilir, istikrarlı çalışma ve tutarlı pelet kalitesi sağlayabilir. Bu sistemler, arıza süresini azaltır ve genel üretim verimliliğini artırır.

Enerji verimliliği bir diğer önemli gelişmedir. Optimize edilmiş iletim sistemleri ve değişken frekanslı sürücüler, üretilen ton başına enerji tüketimini azaltmaya yardımcı olur.

Bu yenilikler sayesinde, Biyokütle Pelet Değirmeni Makineleri artık daha güvenilir ve uygun maliyetli hale geldi, bu da onları hem büyük ölçekli endüstriyel tesisler hem de orta ölçekli biyokütle operasyonları için uygun hale getiriyor.

Daha fazla göster

Tarımsal Atıkların Geri Dönüştürülmesi İçin Neden Biyogaz Pellet Fırlatma Makineleri Önemlidir

2025-12-24

Biyokütle Pelet Değirmeni Makineleri Tarımsal Atık Geri Dönüşümü İçin Neden Esastır?

Tarımsal atık yönetimi dünya çapında büyük bir sorun haline geldi. Biyokütle Pelet Değirmeni Makinesi mahsul artıklarını değerli yenilenebilir yakıta dönüştürerek etkili bir çözüm sunar.

Mısır sapları, buğday samanı, pirinç kabukları ve ayçiçeği kabukları gibi malzemeler genellikle atılır veya açık tarlalarda yakılır. Biyokütle Pelet Değirmeni Makinesi kullanılarak, bu malzemeler endüstriyel ve konut ısıtması için uygun biyokütle peletlerine dönüştürülebilir.

Peletleme işlemi, malzeme hacmini azaltırken enerji yoğunluğunu artırır. Bu, taşımayı ve depolamayı daha verimli hale getirir ve çevresel kirliliği azaltır. Çiftçiler ve biyokütle işleyicileri de atıkları pazarlanabilir ürünlere dönüştürerek ek gelir elde edebilirler.

Gelişmiş Biyokütle Pelet Değirmeni Makineleri, değişken nem içeriği ve karışık ham maddeleri işlemek üzere tasarlanmıştır. Güçlendirilmiş silindirler ve optimize edilmiş kalıp tasarımları, zorlu tarımsal biyokütle işlenirken bile kararlı pelet oluşumunu sağlar.

Döngüsel ekonomi modellerine olan ilginin artmasıyla birlikte, biyokütle pelet üretimi, tarım ve yenilenebilir enerji endüstrileri arasında önemli bir bağlantı haline geliyor.

Daha fazla göster